Custom Servo Motors & Frameless Part Sets for Unique Applications

TruTech designs and manufactures custom engineered servo motors and frameless part sets built specifically for each client’s needs. Unlike catalog options, our motors are created to solve unique challenges by delivering the exact torque, speed and environmental performance your system demands. These custom servo motor application solutions aren’t just tailored to fit — they’re engineered to elevate overall machine performance.

With all our custom servo motor manufacturing done in the USA, TruTech provides more than precision hardware. You gain the reliability of U.S.-based compliance standards, consistent lead times and responsive engineering support from a partner trusted across industries and state lines.

Custom Servo Motor Solutions – Proven in Real Applications

TruTech specializes in developing custom servo motor solutions for OEMs and system designers who require more than off-the-shelf performance. Through our proven optimization process, we fine-tune every variable — torque constant, speed profile, IP-rated sealing, mounting configuration and feedback options such as encoders — to build customized servo motors that integrate flawlessly into demanding environments. The outcome is a precision motion control system designed to perform reliably in the most challenging conditions.

What sets TruTech solutions apart:

- Motors engineered from the ground up, not adapted from generic designs

- Rapid prototyping with stocked components to accelerate time to market

- Full customization of electrical, mechanical and environmental specs — including IP-rated housings and direct drive options

- We’re an OEM servo motor supplier with U.S.-based engineering and manufacturing for predictable delivery and quality assurance

These advantages are proven in action. From servo motor applications in industries such as aerospace, defense, food processing, marine systems and beyond, TruTech motors deliver the precision and performance engineers expect.

Up next, you’ll see examples of how we’ve applied this expertise to create solutions that thrive in the toughest environments.

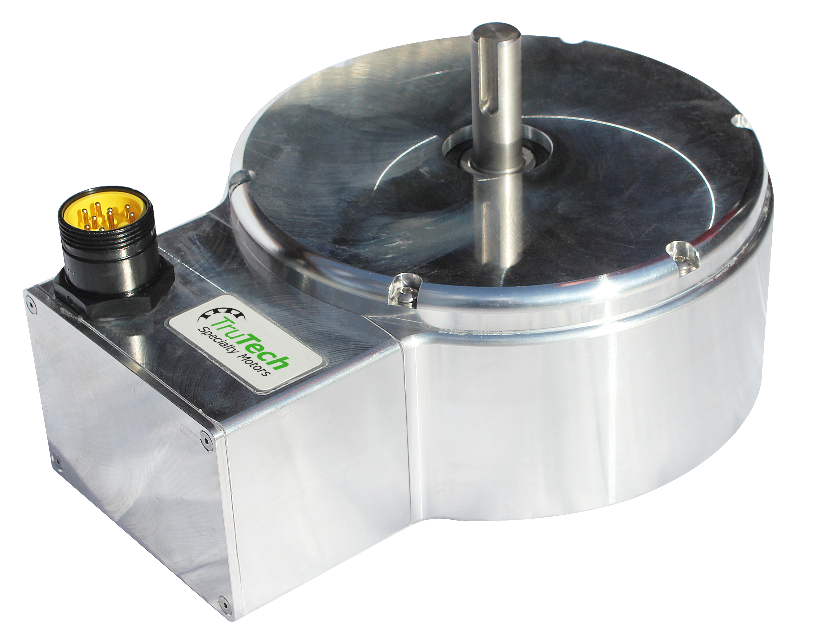

Fitness Equipment

Customer Challenge

In a treadmill application, the client’s original solution used a standard catalog servo motor. The standard motor was designed for general applications, so it was difficult to integrate into the treadmill assembly. Performance was also suffering at low speeds.

TruTech’s Custom Solution

TruTech developed a tailored design for a treadmill motor. For mounting purposes, the mounting brackets were integrated directly into the housing for easy installation. An incremental encoder was also added to the motor for a smoother motion profile to better simulate running on pavement.

Cost-optimization was also a focus of the project, using an aluminum round-body housing and matching front and rear endcaps. This custom design shortened the motor length and increased the overall diameter. All these factors led to a lower overall cost compared to the original motor.

TruTech Solution Impact

- Integral mounting brackets for faster assembly

- Overall size reduced by ~40%

- Smoother motion profile

- Cost-optimized design – 20-30% savings

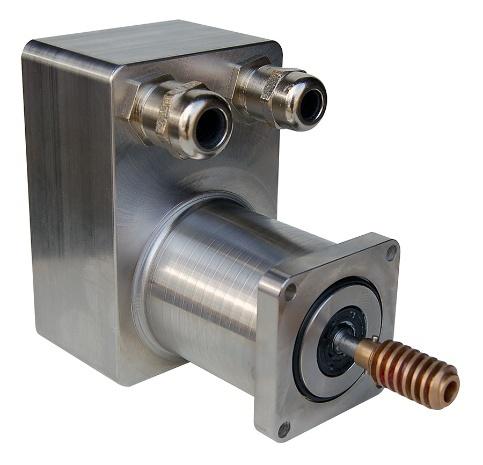

Marine Equipment

Customer Challenge

A leading manufacturer of professional fishing systems needed a lightweight, high-torque motor for a next-generation electric reel. Their goal was to reduce overall system weight by nearly half (from ~23 lbs to 12–13 lbs) while doubling retrieval speed from 5 ft/sec to up to 10 ft/sec under ~20 lbs of line pull. The motor also had to withstand continuous saltwater exposure and intermittent heavy-duty use.

TruTech’s Custom Solution

TruTech engineered a compact brushless DC motor designed specifically for harsh marine environments:

- Optimized magnet and lamination options to shorten length while maintaining torque

- Lightweight housing and shaft design with reduced wall thickness and material mass

- Hard-anodized housing for corrosion resistance in saltwater

- Stainless steel hardware with anti-corrosion treatments

- Custom shaft interface (Woodruff keyway, retaining ring grooves)

- Multiple voltage configurations (12-72VDC)

TruTech Solution Impact

- Enables smaller, lighter reels for easier handling

- Achieves significantly higher retrieval speed without sacrificing pulling power

- Operates reliably in saltwater with minimal maintenance

- Prototype units produced quickly for customer field testing, with scalable production design ready

Water Treatment

Customer Challenge

A client reached out for a solution in a pond aeration application. Because the application is outdoors and exposed to the elements, the motor needed to be fully protected against water ingress. It was also critical to output more torque in the same package. The motor needed to be able to run as fast as 100rpm, but the majority of run time is spent at low speeds, so zero cogging at low speeds was critical.

TruTech’s Custom Solution

TruTech developed a custom direct-drive motor solution by moving from a 8-pole motor design to a 16-pole design. Increasing the pole count enabled a change to the motor’s performance characteristics. The torque capacity of the motor was increased by ~2x, while performance was improved at low speeds — all while staying within the same space constraint.

To survive in the harsh outdoor environment, the stator is completely encapsulated. The motor is rated for IP67 to withstand submersion underwater up to 1m.

TruTech Solution Impact

- Increased torque capacity in same package (~2x)

- Zero cog at low speed

- Submersible IP67 rated

- Encapsulated Stator

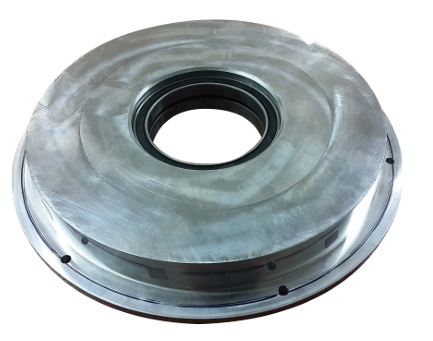

Food Processing

Customer Challenge

In a food processing application, the client required a 3-inch hollow shaft. Additionally, the motors needed to be stackable with free-wheeling mechanical rotating drums.

TruTech’s Custom Solution

TruTech designed a direct-drive outer-rotational motor solution while accommodating a 3” hollow-bore. This means that the stator is on the inside of the motor, and the rotor rotates on the outside of the motor. With a 40-pole design, the motor has a 12” outer diameter. This enables a larger torque capacity as well as allowing for a much larger inner hollow shaft.

The motor is constructed in a pancake style, meaning that it takes less time to manufacture, and the profile of the motor is much slimmer at 2” long. The hub mount style of the motor is what allows for the stacking of the mechanical rotating drums.

TruTech Solution Impact

- Direct-Drive

- Large hollow shaft (3”)

- Pancake style (12” outer diameter, 2” height) – High torque, slim profile

- Stackable hub mounting

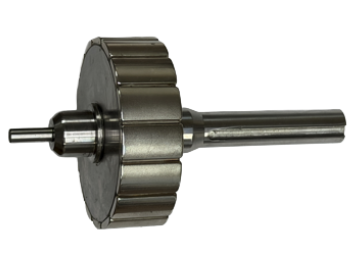

Power Tools

Customer Challenge

A manufacturer needed to transition from pneumatic to electric tools for a high-volume production line, requiring motors that deliver precise torque control and high-speed performance in a compact design. The design had to match existing performance characteristics, minimize noise and vibration to meet ergonomic standards and avoid field service disruptions.

TruTech’s Custom Solution

TruTech crafted a line of custom brushless DC motors tailored for demanding assembly environments: Refined winding configuration to boost electrical performance and align with controller specifications. Enhanced rotor design with dampening features to reduce vibration. Ensured mechanical compatibility with existing setups. Developed iterative prototypes to meet performance targets without altering control parameters.

TruTech Solution Impact

- Powers electric fastening tools for high-volume automotive assembly

- Provides quieter operation and reduced vibration, improving operator comfort and efficiency

- Integrates seamlessly with existing systems, preventing service interruptions

- Delivers precise torque control and faster cycle times, boosting overall productivity

- Improves thermal performance by fitting directly into existing housing

Fire Suppression Systems

Customer Challenge

A defense contractor needed to improve the reliability of servo motors used in automated fire-suppression systems. The motors operated in extremely harsh environments, often submerged in saltwater and rainwater for extended periods. Failures due to corrosion, water ingress and unreliable cable terminations were driving costly maintenance and downtime. The replacement motor had to meet strict military standards while providing a drop-in upgrade to existing systems.

TruTech’s Custom Solution

TruTech developed a sealed IP68-rated servo motor designed for extended underwater operation and naval conditions:

- Housing: Powder-coated housing and endcap with MIL-compliant coating

- Sealing: Housing design for minimal leak paths with shaft and double O-ring seals at the cover

- Cable Interfaces: Cable glands with spring shielding for IP68 protection, replacing legacy connectors to reduce corrosion

- Feedback and Control: Integrated absolute multiturn encoder with thermal protection

- Performance: 6-pole winding configuration designed for compatibility with existing control systems

TruTech Solution Impact

- Operates reliably under extended saltwater submersion without corrosion or performance degradation

- Simplifies maintenance by reducing potential leak points (14 down to 4)

- Drop-in replacement with existing controls, avoiding costly reprogramming

- Improved operational uptime and reduced lifecycle maintenance costs for critical defense systems

Frameless Servo Motors & Part Sets

TruTech designs and manufactures frameless servo motors — custom rotor and stator assemblies engineered for OEM integration. These part sets are built to fit seamlessly within existing machine components, reducing overall system size and weight while delivering uncompromised torque and precision.

Compact by design, frameless motors enable the performance of a direct drive motor without the added bulk of a standard housing. They’re a natural fit for industries where space and reliability can’t be sacrificed — defense, aerospace, robotics and fitness systems among them. With TruTech, every custom servo motor application solution is tailored to strike the perfect balance between performance and integration.

Why Partner with TruTech for Custom Servo Motor Solutions

Choosing TruTech means more than sourcing a motor — it’s building a partnership. Our team engages closely with OEMs, acting as an extension of their own engineering groups to deliver custom servo motor solutions that align with project goals. From first concept to final production, communication and collaboration are central to the process.

- Flexible support from rapid prototypes to high-volume production

- Secure handling of confidential designs for sensitive industries

- Proven success delivering custom engineered servo motors across 20+ sectors

- 100% U.S.-based design and custom servo motor manufacturing for dependable quality and shorter lead times

With TruTech, you gain more than technical expertise. You gain a responsive partner who’s invested in your success.